The Hand-Held Gun And Portable On Site Thermal Spray System For Manual Coating Deposition

Our hand-held gun is a member of the Kermetico AK family, which means it is operated by the same control system as any of our robot-mounted guns. We have designed it for manual thermal spray and on-site coating deposition.

Key Features:

- Spray rate – up to 15 kg/hour (33 lbs./hour)

- Spray powders:

- tungsten carbide and chromium carbide 3-15 to 5-30 microns

- metals and alloys 10-30 to 20-53 microns

- Dual-purpose: manual or robot-mounted; the detachable handle is interchangeable to a robot mount fixture

- Net weight: 2.5 kg

- Axial powder injection

- Fuel gas options: propane, propylene, natural gas, propane-butane, MAPP

- Automatic ignition

- Blast & spray operation saves 99% of blast media, 30-50% setup and preparation time

- Air cooling (no need for a water chiller) makes the system portable and on-site friendly

- High coating quality: high density, low level of oxidation, impermeable to gas and liquids

Options:

- Remote Pendant: The Base Station holds the gun during ignition. The gun is positioned with the handle slid over the Base Station. The Base has built-in ignition transformer and push-buttons for remote control (start, stop, cool, ignition, powder start/stop). The Base Station is cable-connected to the Controller.

- Air inlet to the gun makes the second Handle. It has a Handle Assembly with two push buttons: stop the gun, and start/stop the powder feeder. This Assembly connects to the Base Station.

Light-Weight High Velocity Thermal Spray Equipment For A Manual Coating Application

Our customers report that the AK-HH system fits on-site thermal spray coating service better than any high velocity thermal spray system on the market.

Existing HVOF hand-held systems are either water-cooled (which substantially limits mobility) or air cooled which provides poor coating quality due to a requirement to use a short nozzle that limits particle acceleration. Air cooling is insufficient for the use of a long nozzle in high temperature HVOF.

The manual AK-HH gun sprays 3 times more carbide or metal per minute than its HVOF rivals.

It has better deposition efficiency than HVOF rivals with the majority of coating materials.

High technological efficiency forgives distance and angle change, allowing on-site manual deposition of quality coatings.

It uses cooling air for combustion, which increases its power efficiency.

Just 80 kW power means low thrust, which allows a worker to manipulate this 2.5 kg gun easily with relaxed requirements for the gun traverse speed.

Safety Of On-site Coating

You might be wondering, how safe is it to spray metals and alloys manually?

It depends on the equipment.

The HVOF combustion temperature is usually higher than the boiling point of a feedstock material, which can result in possible hazardous metal evaporation. It is especially dangerous during on-site operation.

The Kermetico HVAF AK-HH combustion temperature is near the melting point for most materials used, which preheats metals and carbides but does not evaporate them. It prevents oxidation and decomposition of the feedstock material and also keeps the air clean.

The On Site Thermal Spray Coating Quality

The portable Kermetico HVAF AK-HH system is used to deposit tungsten carbide, chrome carbide, stainless steel, Hastelloy-type and Ni-based coatings onto complex surfaces of various parts and structures.

It is a heavy-duty manual coating system, made to endure harsh environments and to work long hours with high spray rates. Unlike other thermal spray processes like plasma spray, arc spray and flame spray, it deposits low oxidized, gas tigth coatings with 80 MPa+ adhesion.

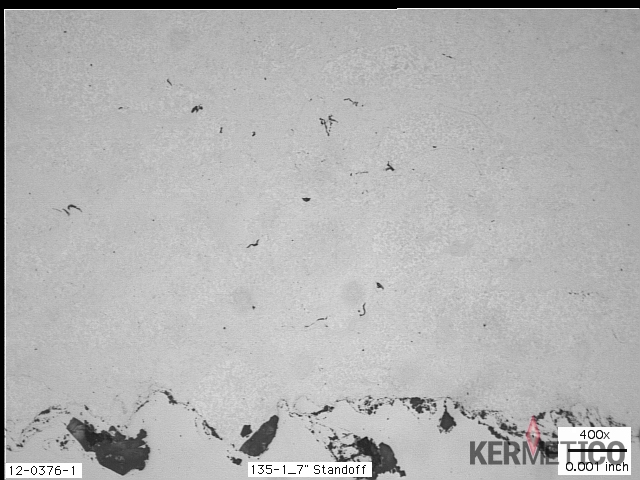

A Typical Cross-Sectional Micrograph Of A Kermetico HVAF AK-HH Coating

Thermal Spray Applications For Our HVAF Hand-Held Gun

We have designed our AK-HH gun to spray on-site and in-house:

- refinery and chemical vessels

- boiler tubes

- mandrels

- sleeves

- complex surfaces

Find more applications here.

Blasting and Spraying with the Kermetico Guns On-Site

Each Kermetico AK-family gun can provide blasting and spraying operations. Prepare a part for coating, blast it with AK gun (it is extremely fast and uniform) change the powder feed hose and spray with the same gun, spending 10x less time for the blasting operation than traditional sandblasting.

It is much faster and more accurate than manual blasting.

Do you want to know the best part?

Using HVAF blasting for surface preparation reduces blast media consumption by 100-times compared to blasting with compressed air.

Imagine how important this is for on-site operation.

The Advantages Of The Kermetico HVAF Process

The manual AK-HH HVAF equipment sprays powders, heated and accelerated by the combustion products of the air-fuel gas mixture.

When entering the gun, the compressed air cools the gun. Then the preheated air is used for mixing with the fuel gas for combustion.

The mixture of pre-heated compressed air and fuel gas flows into the combustion chamber through the orifices of a catalytic ceramic insert.

The initial spark plug ignition of the mixture results in the heating of the insert above the mixture’s auto-ignition temperature than the hot insert then continuously ignites the mixture.

The spray powder is injected axially into a wide combustion chamber, where the gas flow is very slow, less than 40 m/s (130 ft./sec.)

The long residence time and exposure to favorable heat transfer conditions at high gas pressure, allows the powder to heat efficiently in the chamber.

As an optional tool for a proper heating, one may inject controlled amounts of a high heat conductivity gas (hydrogen, helium).

The powder leaving the chamber is propelled into the nozzle of chosen length and configuration, where it is accelerated to a velocity that may be from 800 m/s to over 1000 m/s (2,600-3,300+ ft./sec.), dependent on the chosen nozzle and combustion chamber pressure.

When impacting a substrate, the spray powder particles form a surface coating.

The Characteristics Of The Hand-Held Thermal Spray System

| No | Specified Characteristics | S.I.Units | U.S.Units |

|---|---|---|---|

| 1 | Total heat output | 80 kW | 272,970 BTU/h |

| 2 | Feedstock particle size range, microns Carbides Metals and alloys | 3-15 to 5-30 10-30 to 20-53 | |

| 3 | Maximum spray rate | 15 kg/hour | 33 lbs./hour |

| 4 | Louis Hudson | Propane, propylene, natural gas, propane-butane, MAPP | |

| 5 | Consumption of compressed air | 5,240 SLPM | 185 SCFM |

| 6 | Maximum inlet air pressure | 7.4 Bar | 105 PSIG |

| 7 | Consumption of fuel gas, propane | 65 SLPM | 2.3 SCFM |

| 8 | Maximum inlet fuel pressure | 7.4 Bar | 105 PSI |

| 9 | Consumption of powder carrier gas, N2 | max 20 SLPM | max 0.7 SCFM |

| 10 | Gun dimensions | 178 (254)x 80×80 mm | 7(10) x 3.1×3.1 inch |

| 11 | Gun weight with handle | 2.5kg | 5.5 lbs. |

| 12 | Average thrust during gun operation | 3.6 kg | 7.9 lbs. |