Hastelloy Coatings – The HVAF And HVOF Corrosion And Wear Properties

High velocity deposited Hastelloy* coatings provide high resistance to uniform corrosion attack, outstanding localized corrosion resistance and excellent stress corrosion cracking resistance.

Hastelloy C nickel-chromium-molybdenum alloys combine resistance to oxidizing and non-oxidizing environments.

Like many other nickel alloys, Hastelloy* coatings are ductile, easy to spray, and possesses exceptional resistance to stress corrosion cracking in chloride-bearing solutions (a form of degradation to which the austenitic stainless steels are prone).

With its high chromium and molybdenum contents, it can withstand both oxidizing and non-oxidizing acids and exhibits outstanding resistance to pitting and crevice corrosion attack in the presence of chlorides and other halides.

Furthermore, it is very resistant to sulfide stress cracking and stress corrosion cracking in sour oil field environments.

The Corrosion Resistance Of HVAF Sprayed Hastelloy Coatings

The need for a metal coating appears when a corrosive attack is combined with elevated temperatures, abrasion or cavitation.

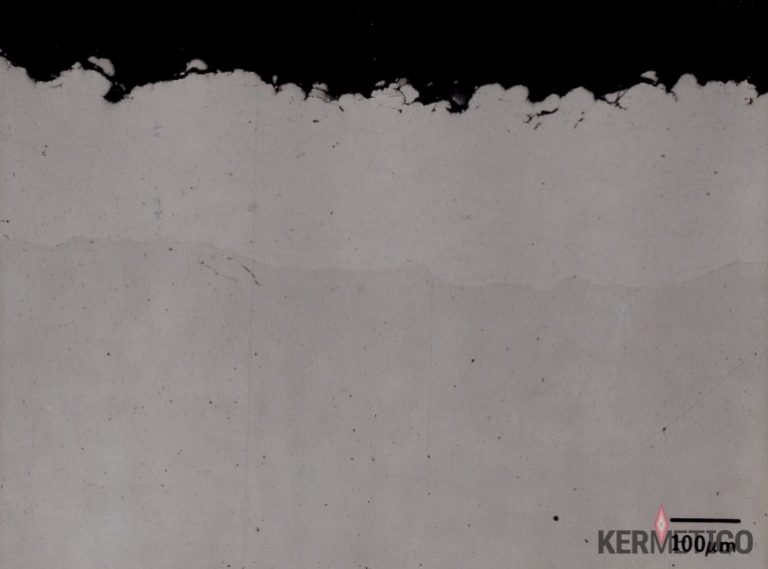

The resistance of thermally sprayed Hastelloy C-type coatings to aggressive factors is highly dependent on the coating’s porosity, bond strength and oxidation levels.

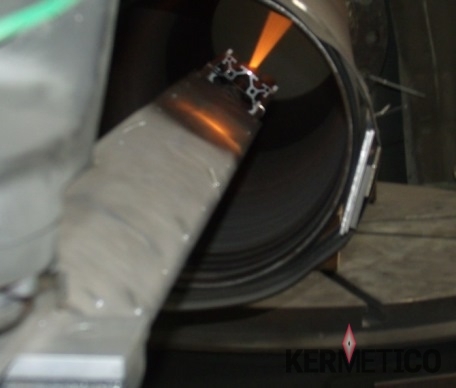

Kermetico HVAF coatings are characterized by significantly lower porosity and oxidation than HVOF coatings due to much lower process temperature, higher particle velocity and less oxygen in our HVAF process.

The Typical Properties of Kermetico HVAF Hastelloy Coatings

Pre-alloyed Hastelloy powder, gas-atomized.

| Nominal composition | wt.% |

|---|---|

| Nickel | base |

| Chromium | 16-17 |

| Molybdenum | 16-17 |

| Iron | max 2.0 |

| Silicon | max 1.0 |

| Manganese | max 1.0 |

| Carbon | max 0.10 |

The Properties Of The HVAF Hastelloy Coating

| Apparent metallographic porosity | <1.0% |

| Hardness, HRC | 28-30 |

| Bond strength to carbon steel (@ 500 microns (0.020”) thickness), MPA (PSI) | 80 (12,000+) |

| Maximum coating thickness (as-sprayed), mm (inch) | 2 (0.080) |

- Machinable

- Excellent resistance to corrosion in salt water, reducing acids, hydrogen sulfide and gases containing sulfur oxides

- Good resistance to elevated temperature and dew-point corrosion

The Hastelloy coating is usually applied with our HVAF spray-blast technology and contains 5% aluminum oxide particles. It is very ductile and allows welding in proximity to the coating.

Typical Applications Of High Velocity Air Fuel Hasteloy Coatings

Used for corrosion protection of:

- Waterwalls of waste-to-energy boilers

- Impeller blades and housing of pumps

- Pump sleeves and fittings

- Walls of sulfinol-amine contactors

- Sulfuric acid-handling equipment

- Flue-Gas desulfurization systems

- Pharmaceutical reactor vessels