Aluminum Coating: High Velocity Thermal Sprayed, Dense, Non-Oxidized

Kermetico HVAF equipment efficiently deposits high-bond, dense and non-oxidized aluminum coatings. The low oxygen content in the Kermetico HVAF process, high and uniform particle velocity result in high coating density and bond strength.

The low oxygen content in the Kermetico HVAF process, high and uniform particle velocity result in high coating density and bond strength. It results in possibility to clad thick layers of aluminum with our equipment.

High Velocity Aluminum Coatings

Numerous publications devoted to spraying aluminum by HVOF and cold spray processes display an industry need for a method to form a dense non-oxidized aluminum coating.

Spray clad aluminum coatings with such properties are used to repair/rebuild worn light-weight parts, to form a corrosion resistant layer with high electrical conductivity, to protect magnesium substrates and in additive manufacturing.

We are not aware of any research devoted to the HVAF deposition of Al coatings, so we just spray it in-house and produce specialized HVAF equipment for low-melting point materials spray cladding.

The Properties Of HVAF Al Coatings

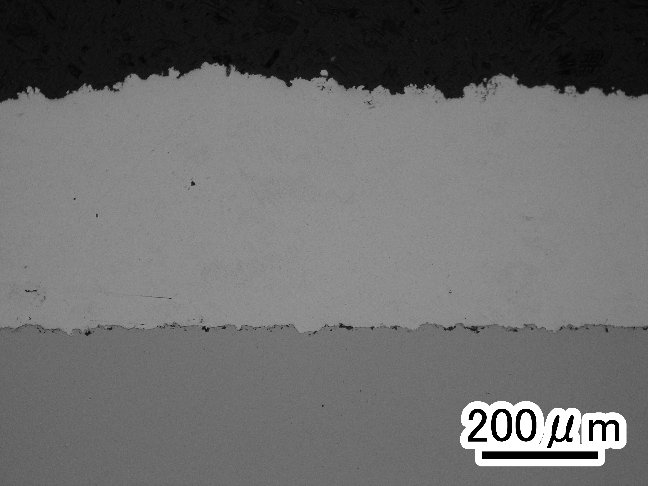

Kermetico HVAF Al coatings demonstrate a bulk-like structure, high bond strength and low level of coating oxidation.

Al powder nominal composition (wt.%):

- Aluminum 99.5%

Aluminum Coating Properties

| Apparent metallographic porosity | <1.0% | ||

| Hardness, HV | 105 | Maximum operating temperature, oC (oF) | 500(932) |

| Hardness, HV | 105 | Maximum operating temperature, oC (oF) | 500(932) |

| Maximum coating thickness (as-sprayed), mm (inch) | 12 (0.500) and more |

A Comparison Of HVOF, HVAF And Cold Spray Methods To Spray Pure Al coatings

The melting point of Al is 660°C (1,220°F), while the boiling point is 2,470°C (4,478°F)

Commercially available HVOF systems are not designed to handle low melting point metals. he typical combustion temperature varies from 3,100°C | 5,612°F for oxy-kerosene to 3,200°C | 5,792°F for oxy-hydrogen. Both are substantially higher than the boiling point of aluminum. This creates a risk of complete vaporization of the Al within the combustion chamber or nozzle, Al condensate build-up on the nozzle leads to clogging and the excess oxidation of the Al coating. Those risks make HVOF aluminum spraying an unfavorable candidate. This creates a risk of complete vaporization of the Al within the combustion chamber or nozzle, Al condensate build-up on the nozzle leads to clogging and the excess oxidation of the Al coating. Those risks make HVOF aluminum spraying an unsuitable candidate.

The cold spray deposition of Al is harder than other soft materials such as Zn and Cu. This is attributed to its high heat capacity which makes it harder to achieve shear instability conditions during impact, regardless of its low melting point and low yield strength. While some good samples of deposited Al were produced by different researchers, the overall cost of the cold spray process makes this application too expensive for industrial usage.

The Kermetico HVAF SL gun is designed specifically to spray low melting point materials.

It has:

- lower combustion temperatures (1,960-2,100°C | 3,560-3,812°F) than the boiling point of Al preventing material evaporation

- inert gas shroud minimizing oxidation

- wide nozzle preventing nozzle clogging

- higher particle velocity than HVOF and higher particle energy than Cold spray

- lower investment costs and much lower operating costs than HVOF or Cold Spray

All of this result in affordable Al coatings with close to zero porosity, zero gas permeability and high bond.

The Typical Applications For Kermetico HVAF Aluminum Coatings

- Repair of worn light-weight parts made of aluminum, magnesium or its alloys

- Corrosion protection of magnesium parts

- Functional coatings

- Additive manufacturing